Lpg Gas Batch Fryer China Pressure Fryer Eastern Hotel Supply Gas Open Fryers Factory MDXZ-25

Key benefits:

Unlock Crispy, Juicy Perfection:The MDXZ-25 Commercial Pressure Fryer

1. Pressure Frying Excellence: Seals in natural juices and flavors while achieving that signature golden-brown, crispy crust in significantly less time. Ideal for fried chicken, wings, and other poultry.

2. High-Capacity & High-Efficiency: The generous 25-liter capacity handles substantial batch volumes, perfect for busy restaurants, QSRs, hotels, and catering operations. Heating element ensures rapid heat recovery and consistent cooking temperatures.

3. Robust Industrial Power: Designed for professional kitchens, it operates on 1-Phase 220V / 50Hz power, providing the stable and powerful energy required for continuous, heavy-duty use.

4. Simple & Reliable Mechanical Controls: Featuring an intuitive mechanical control panel, the MDXZ-25 is exceptionally user-friendly. Staff can operate it with minimal training, ensuring consistent results shift after shift. Enjoy straightforward operation and reduced downtime.

5. Durable & Streamlined Design: Built with commercial-grade stainless steel components for longevity and easy cleaning. The design prioritizes functionality and reliability in a high-heat kitchen environment.

6. Cost-Effective Operation (Excludes Oil Filtration): This model focuses on core pressure frying performance. The absence of an integrated oil filtration system offers a more budget-conscious entry point for businesses prioritizing essential pressure frying capabilities. (Consider adding compatible external filtration options as accessories).

Food grade stainless steel frypot

The mechanical control panel is easy to operate and the timing reminder function can save labor costs.

♦ 24 precision-machined copper nozzles ensure 15% longer lifespan

Fast Preheating: Achieves 180°C within 15 minutes.

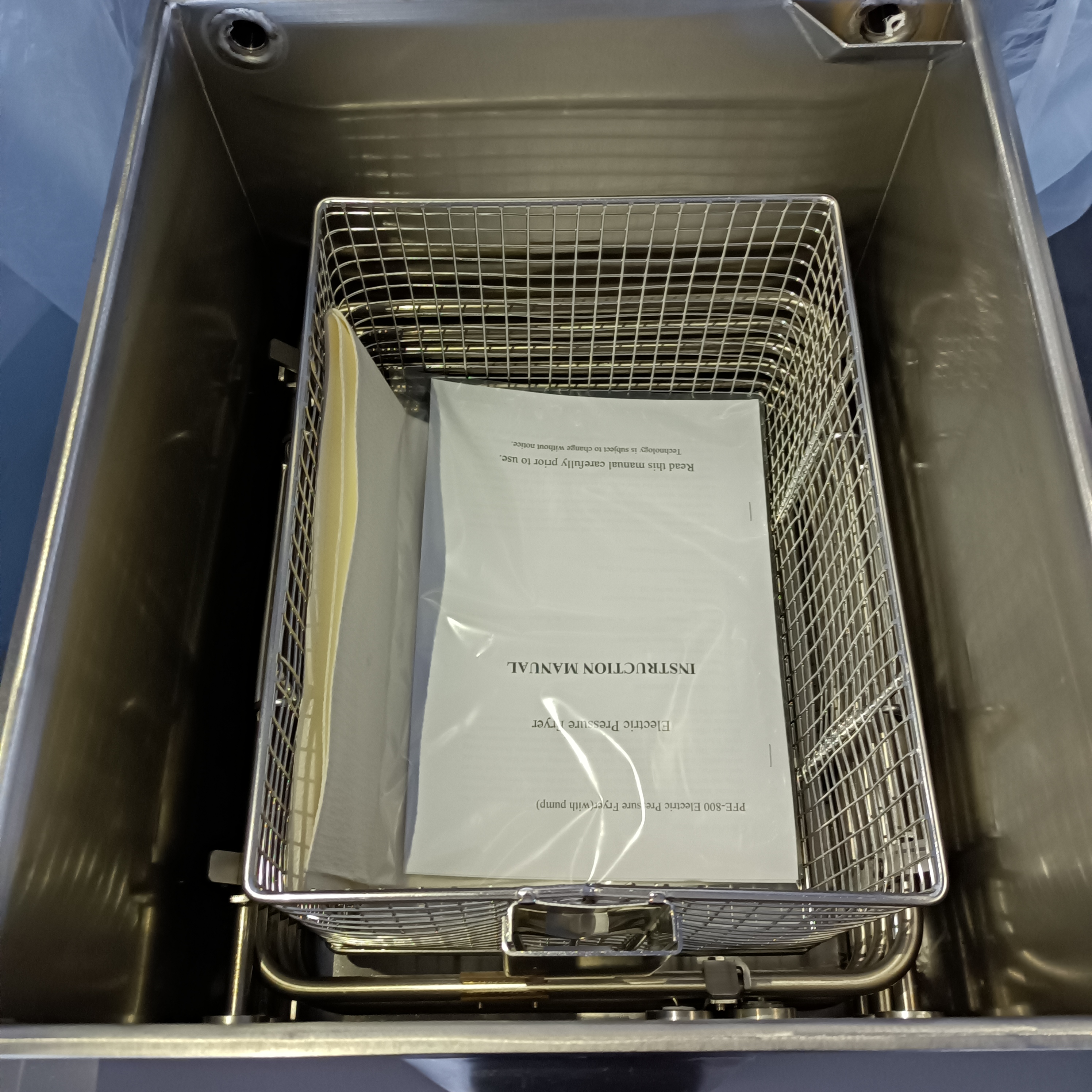

The standard configuration of the fryer is normal basket. If you need layered Basket, please contact Customer Service

Why Choose the MDXZ-25?

Superior Product Quality: Pressure frying delivers juicier, more flavorful results.

Increased Throughput: Cook faster than traditional fryers, serving more customers.

Enhanced Yield: Retain more moisture, meaning more sellable product per batch.

Operational Simplicity: Easy-to-use mechanical controls minimize errors and training time.

Commercial Durability: Built to withstand the rigors of a professional kitchen.

Value Proposition: Offers essential pressure frying power at a competitive price point.

» The mechanical control panel, easy to operate.

» High efficiency heating element.

» Shortcuts to save memory function, time constant temperature, easy to use.

» Equipped with thermal insulation, save energy and improve efficiency.

| ied Voltage | 3N~380V/50Hz-60Hz / 3N~220V/50Hz-60Hz |

| Heating type | Electric/LPG/Natural Gas |

| Temperature Range | 50-200 ℃ |

| Dimensions | 960*480*1195mm |

| Packing Size | 1030*510*1320mm |

| Capacity | 25L |

| Net Weight | 110 kg |

| Gross Weight | 130 kg |

| Construction | Stainless steel frypot, cabinet and basket |

| Input | Natural gas is 1260L/hr. LPG is 504L/hr. |

Why Choose MJG ?

» Boost kitchen productivity.

» Deliver unmatched flavor and texture.

» Save on operational costs.

» Impress your customers with consistently delicious results.

Technical Specifications:

» Power Input Type: Gas/electric

» Construction: Stainless steel frypot, basket/pot cover with aluminized sides

» Baskets: Normal basket. (could make up the price difference and change the layered basket).

» Control: Mechanical panel, easy to operate.

» Casters: 4 casters

Ideal For:

» Fried chicken franchises QSR chains

» Hotel kitchens

» Food production facilities

Service Commitment:

» 1-Year Warranty on Core Components

» Global Technical Support Network

» Step-by-Step Video Guides Included

Superior Customer Support and After-Sales Service

Choosing a MJG pressure fryer is not just about choosing a high-performance device but also about selecting a reliable partner. MJG provides comprehensive after-sales services, including installation guidance, usage training and on-line technical support. No matter what issues customers encounter during use, MJG's professional team can provide timely assistance to ensure the equipment is always in optimal condition.

1. Who are we?

MIJIAGAO, headquartered in Shanghai since its establishment in 2018, operates a vertically integrated manufacturing facility specializing in commercial kitchen equipment solutions. With a legacy spanning over two decades in industrial craftsmanship, our 20,000㎡ factory combines human expertise and technological innovation through a workforce of 150+ skilled technicians, 15 automated production lines, and AI-enhanced precision machinery.

2. How can we guarantee quality?

6-stage validation protocol + ISO-certified process control

3.What can you buy from us?

Open fryer, Deep fryer, counter top fryer, deck oven, rotary oven, dough mixer etc.

4. Competitive Edge

Direct factory pricing (25%+ cost advantage) + 5-day fulfillment cycle.

5. What is the payment method?

T/T with 30% deposit

6. About shipment

Usually within 5 working days after receiving the full payment.

7. What services can we provide?

OEM service | Lifetime technical support | Spare parts network | Smart kitchen integration consulting