China Pressure Fryer China Electric Chicken Pressure Fryer Electric high-pressure fryer 24L PFE-600

Why Choose A Pressure Fryer

For years, pressure frying has been utilized in many food chains across the globe. Global chains love using pressure fryers (also referred to as pressure cookers) because they create a delicious, healthy product attractive to today’s consumers, while at the same time saving on oil and labor costs.

» Faster Cook Times

One of the top benefits of switching to pressure frying is how much shorter the cook times are. Frying in a pressurized environment leads to faster cooking times at a lower oil temperature than traditional open frying.

» More Menu Possibilities

While poultry remains one of the most popular products made in a MJG pressure fryer, it is a highly versatile method of cooking.

» Better Food Quality

With this method of cooking more moisture and juices are retained in the food, meaning less shrinkage. Pressure frying gives customers a tender, delicious product that’ll keep them coming back for more.

» Consistently Great Taste

MJG pressure fryers utilize advanced foodservice technology that enables quick cook times and a consistently great flavor since the food’s natural flavors and nutrients are sealed in while any extra frying oil is sealed out.

Features

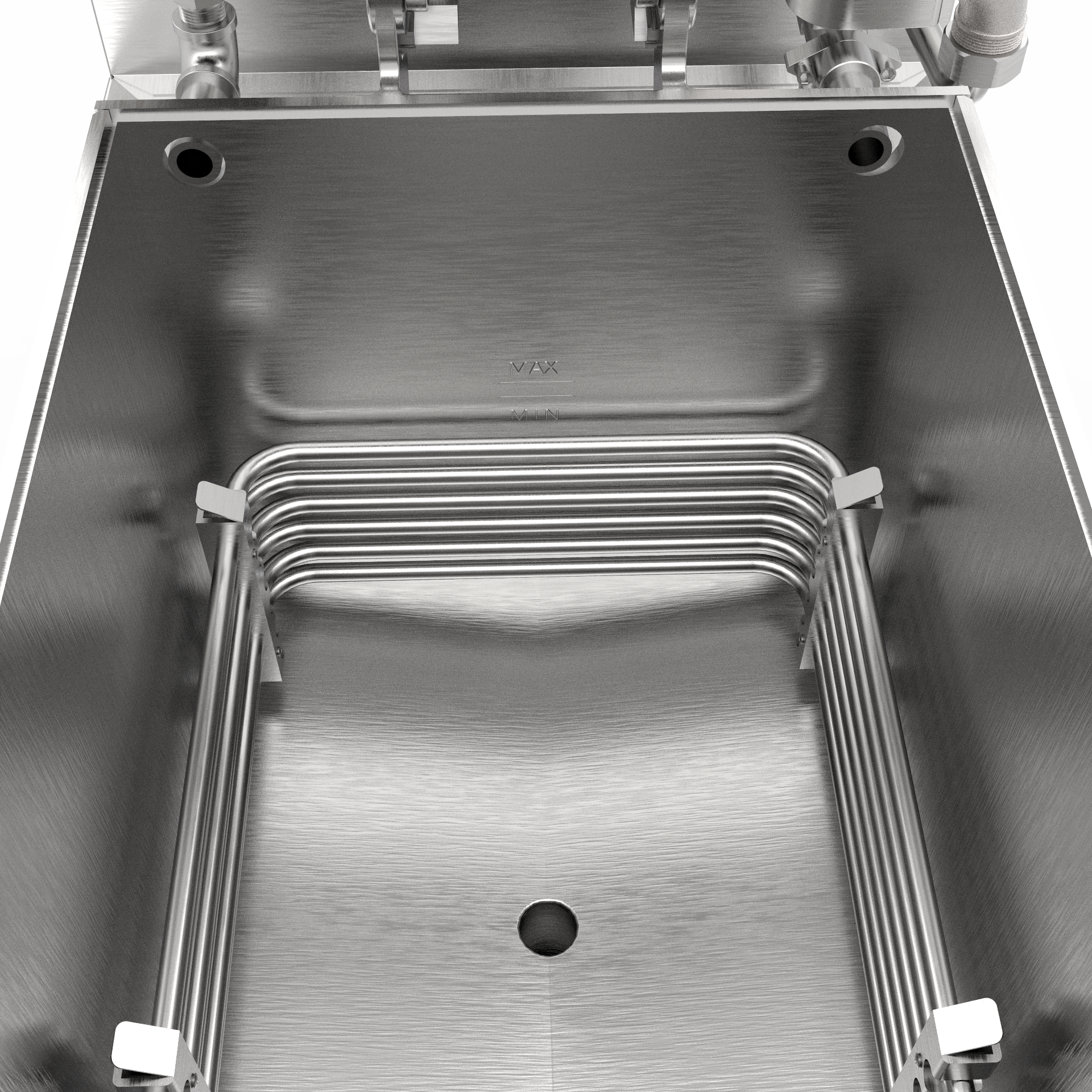

▶ All stainless steel body, easy to clean and wipe, with long service life.

▶ Aluminum lid, rugged and lightweight, easy to open and close.

▶ Built-in automatic oil filter system, easy to use, efficient and energy-saving.

▶ The four casters have large capacity and are equipped with brake function, which is easy to move and position.

▶ The computer control panel is more convenient and simple to operate.

Specs

| Specified Voltage | 3N~380v/50Hz (3N~220v/60Hz) |

| Specified Power | 13.5kW |

| Temperature Control Range | 20-200 ℃ |

| Dimensions | 960 x 460 x 1230mm |

| Packing Size | 1030 x 510 x 1300mm |

| Capacity | 24L |

| Net Weight | 135 kg |

| Gross Weight | 155 kg |

| Control Panel | Computer Control Panel |

Remarks

Power Input Type: Electric or Gas

Voltage: 3N~380V/50Hz can be changed to 3N~220V/50Hz

Frypot Cover: pot cover with aluminized sides

Basket: Normal basket (It's can make up the difference and replace the layer baske)

Construction: Stainless steel frypot, cabinet and basket.

With pressure frying, all that oil-burdened steam is captured and exhausted into a hood above. This reduces greasy film and odors from building up in the surrounding area. With less grease and odor build-up, fewer labor hours can be spent on cleaning and more time can be spent on making profits.

One of the significant advantages of MJG pressure fryers is the built-oil filtration systems. This automatic system helps extend oil life and reduces the maintenance required to keep your pressure fryer functioning. At MJG, we believe in making the most effective system possible, so this built-in oil filtration system comes standard on all our pressure fryers.

The standard match of the fryer is the normal basket. If you need a layered basket, please contact our sales staff.

Superior Customer Support and After-Sales Service

Choosing a MJG fryer is not just about choosing a high-performance device but also about selecting a reliable partner. MJG provides comprehensive after-sales services, including installation guidance, usage training and on-line technical support. No matter what issues customers encounter during use, MJG's professional team can provide timely assistance to ensure the equipment is always in optimal condition.

Why Choose MJG ?

» Boost kitchen productivity.

» Deliver unmatched flavor and texture.

» Save on operational costs.

» Impress your customers with consistently delicious results.

Technical Specifications:

» Stainless Steel Construction: 304 grade body

» Control Panel Computerized (IP54 Rated)

» Intelligent Control: Computer Digital panel (±2℃) + preset programs

» Equipped with layered basket

» Maintenance: Filter system for easy cleaning.

Ideal For:

» Fried chicken franchises QSR chains

» Hotel kitchens

» Food production facilities

Service Commitment:

» 1-Year Warranty on Core Components

» Global Technical Support Network

» Step-by-Step Video Guides Included

1. Who are we?

MIJIAGAO, headquartered in Shanghai since its establishment in 2018, operates a vertically integrated manufacturing facility specializing in commercial kitchen equipment solutions. With a legacy spanning over two decades in industrial craftsmanship, our 20,000㎡ factory combines human expertise and technological innovation through a workforce of 150+ skilled technicians, 15 automated production lines, and AI-enhanced precision machinery.

2. How can we guarantee quality?

6-stage validation protocol + ISO-certified process control

3.What can you buy from us?

Open fryer, Deep fryer, counter top fryer, deck oven, rotary oven, dough mixer etc.

4. Competitive Edge

Direct factory pricing (25%+ cost advantage) + 5-day fulfillment cycle.

5. What is the payment method?

T/T with 30% deposit

6. About shipment

Usually within 5 working days after receiving the full payment.

7. What services can we provide?

OEM service | Lifetime technical support | Spare parts network | Smart kitchen integration consulting